Ti-CFRP interface, a review

- Alberto Ricciulli

- 28 set 2020

- Tempo di lettura: 9 min

Aggiornamento: 9 ott 2020

A review on the Titanium Carbon Fiber Reinforced Polymers (CFRP) Composites

Authors: Leann Kampley, Alberto Ricciulli, Bryan Contreras

Department of Aerospace Engineering, San Diego State University

Department of Mechanical Engineering, San Diego State University

Abstract:

Fiber Metal Laminates (FMLs) combine the strength and fatigue properties of metals with the lightweight and stiff properties of composites. Sheets of Titanium (Ti) alloy bonded with plies of Carbon Fiber Reinforced Polymers (CFRP) form one type of FML. Fighter aircraft, such as the F/A-18, are designed be fast, travel far, and carry multiple weapon systems; in order to accomplish this, the aircraft is required to be as lightweight as possible. Aircraft of this type are also required to endure high cycle fatigue when maneuvering through supersonic flight and when taking arrested landings on carriers. Therefore, the materials used in the skin structure are required to have a high fatigue life. Ti-CFRP encompasses these needs, and is suitable for use in aerospace applications. The interface between the metal and composite layer is of interest, since it is a stress riser and commonly the onset crack growth. This review will explore the surface treatments of Ti-CFRP, interface characterization methods, and explain interface mechanics. Once the types of treatments to Ti-CFRP are explored, specimens with varying degrees of treatments will be compared with one another to reveal that, with more exposure to surface treatments, the interface has higher strength and fracture toughness.

Keywords:

A. Surface treatment

B. In-Plane Fracture Toughness

C. Strength

D. Fiber Metal Laminates

I. Introduction

The interface between titanium and carbon-fiber reinforced polymers (CFRP) is one that consists of three different material classes: metals, ceramics, and polymers. This interface is mainly used in aerospace applications, taking the advantages of the initial composite (being lightweight, having high strength and stiffness) and combining them with that of metals (having high impact resistance and bearing strength) [6]. In addition, the hybrid composite experiences an elevated damage tolerance and reduced the overall cost of material [1,2]. While many of the fiber-metals utilized currently in commercial aircraft, such as the Airbus A380, are made from aluminum alloys, titanium does not experience galvanic corrosion when used in conjunction with CFRP [2]. Furthermore, according to Li et. al., fiber metal laminates (FMLs) based on aluminum alloys consist of limitations when experiencing higher temperatures, while titanium has properties that meets the needs not just of commercial aircraft but military vessels as well [3]. In this review, the bond between the two dissimilar interfaces of titanium and CFRP will be explored, followed by the characterization methods performed to determine the interface properties, concluding with the mechanics behind those properties.

II. Forming the Fiber-Metal Interface

The Ti-CFRP interface can most easily be seen when looked at in fiber-metal laminates. In order to create the laminate, as with most composites, thin sheets of titanium are laid-up with plies of CFRP; for example, Li et. al. had a layered sandwich of three plies of CFRP with the titanium sheets being on the outside of the laminate [3]. The laminate is then vacuum-bagged, allowing the excess resin to flow out of the laminate. Afterward, the laminate is then cured at room temperature before experiencing post-curing in either an autoclave or oven [3]. It should be noted that using an autoclave to create the laminates is ideal, as it applies more pressure to the laminate to evenly distribute the resin throughout all parts of the laminate. Creating the laminate essentially solidifies the bond between the resin and the titanium, allowing for the interface to be formed.

III. Interface Integrity Factors

For titanium and CFRP, the main bond is between the resin/polymer that is in the CFRP and the titanium sheet. Two main factors affect this bond: temperature and surface roughness.

In general, at high temperatures, at which supersonic aircraft operate, the physical bond between the polymer and titanium becomes relatively weak [7]. While epoxy is commonly used as the resin between Ti-CFRP due to being able to perform better at higher temperatures than other matrix materials, it requires a longer period of time to achieve complete cure [1], as it can only withstand temperatures up to 200°C before failure [2]. In order to mitigate this, high temperature polymers (such as polyimide [2]) should be utilized when creating the interface between titanium and CFRP.

Additionally, the surface roughness of the titanium sheets determines the durability of the bond between the polymer and metal. When the titanium sheet has a higher surface roughness, the bond strength is increased, as this increases the surface area that the resin is able to flow through [5]. This surface roughness can be achieved on either the macro or micro scale through either mechanical treatment, chemical treatment, or electrochemical treatment. These treatments to increase the roughness of titanium can be applied either individually (ie. just mechanical) or as a combination of any of the three.

IV. Surface Treatment of Titanium

All surface treatments are done to the titanium sheets prior to laying up the material with CFRP. Mechanical treatments that are done to titanium sheets prior to bonding are in the abrasive form, such as sand blasting or grit blasting [3,6]. These treatments increase the macro-roughness of the surface of titanium. It should be noted that after performing this treatment, the titanium sheets need to be cleaned with a solvent before being laid up with the CFRP. Electrochemical treatments can be seen in the form of anodization, which creates an oxide layer in the titanium and increases its micro-roughness [2]. Chemical treatments are mainly used in the form of annealing, and normally in combination with mechanical treatments [3]. This is due to the fact that annealing removes any residual stresses created by the abrasive treatment, but also creates an oxide layer, which further increases the micro-roughness of the surface.

V. Interface Mechanics

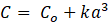

The strain energy release rate is calculated through experimentation using the Single Cantilever Beam (SCB) test. Four plies of 0/90 CFRP are stacked on 1.62mm titanium alloy. The specimen is 3.2mm thick and 25mm in width (width = b). The crack is 50mm in length (crack length = a), and has 55mm free end length from the crack end. As the force P is applied, the force, displacement, and crack growth are recorded. The experimental compliance is calculated and is equal to the displacement divided by the applied load, giving:

where k is the slope of the of the compliance (C) and crack-length (a) plot. The strain energy release rate, G, is calculated and is a function of the force, specimen width, and change in compliance with respect to the crack length:

The strain energy release rate G is a mixed mode parameter composed of mode 1 (opening) and mode 2 (in plane shear/ sliding), as shown in the equation below:

G1 represents mode 1 and G2 represents mode 2. Mode 2 is a result of the orthotropic composite material. Orthotropic materials have different properties in the longitudinal, transverse, and orthogonal directions. This Orthopedic condition results in unexpected strains, and stresses when compared to typical isotropic materials. In the equation above, k= shear correction factor 5/6, h= half the specimen thickness, and E11, E13, E33 are taken from stiffness matrix.

VI. Interface Characterization

Experimental characterization is necessary to provide data needed for analysis and design and to understand the material response under different conditions. Composite properties are dominated by the behavior of the interface between the matrix and the reinforcement. It is at the interface that the load transfer between the two materials takes place and is generally weakest. As such, it is paramount to understand what the material properties will be for a given composites at its interface.

Given the applications of the material in this case of study, the main focus is dedicated in investigating the mechanical properties of Ti-CFRP joints. These properties include, but are not limited to: properties in tension (ie. elastic modulus, ultimate tensile stress), compression, in-plane shear properties (strain energy, ultimate shear strength), flexural properties; measures of in-plane fracture toughness (Gc,K).

It must be noted that, in order to obtain such properties, different tests have to be performed. The guidelines for the test procedures and sample preparation are dictated by the American Society of Testing Material (ASTM). The following sections will refer to actual studies performed to obtain the properties in question by different researchers in the field.

a. Properties in tension

Wang et al. investigated the characterization of a carbon fiber reinforced epoxy and titanium interface using ARAMISv6.3.0 digital image correlation (DIC) system [8]. DIC provides live full field surface strain over time data using digital images recorded at set time intervals during tensile testing. In this study, the intervals were set at 1 second. The DIC measurement is based on the distribution of random speckles on a specimen surface. These speckles are generated using black and white spray paint. The DIC measurement is simultaneously confronted to an extensometer measurement to compare the results. The specimens were tested under quasi-static conditions until failure. This kind of testing produces a load vs. displacement curve from which we can determine Young’s modulus (E), yield strength, ultimate tensile strength and Poisson’s ratio. The results show an average elastic modulus of 210 Mpa

b. Shear properties.

As previously mentioned, Li et al. studied the mechanical behaviors of Ti/CFRP/Ti laminates with different surface treatments performed on the titanium sheets [3]. In this paper, they investigated the mechanical performance of the laminates in shear by performing a single lap shear experiment at a loading rate of 1mm/min according to ASTM D1002. Three types of samples were prepared with different surface treatments on the titanium sheets: (1) as received and annealed; (2) sandblasted and annealed; (3) sandblasted, anodized, and annealed. The results show a significant increase in the shear as well as the overall mechanical performance of the hybrid composite with the surface treatments. For the samples without sandblasting, the interface failed at the early loading stage, with the sample showing an approximate linear elastic behavior. For the sandblasted samples, after the initial elastic loading stage, the load-displacement histories became nonlinear, which were caused by the plastic deformation of epoxy and strong interfacial bonding. After the non-linear region, the (2) and (3) specimens obtained another elastic region, which was caused by the cohesive failure of epoxy and/or oxide layer failure. Due to the micro-porous structure of anodic film, the anodized sample obtained the maximum apparent shear strength.

c. Fracture toughness.

Yu et al. analyzed the different mechanical behavior of FMLs with different exposure times to a hygrothermal environment and different surface treatments [9]. The treatments involved were: Ti/CF (titanium plates were sandblasted; CFRPs were as received); Ti-Anodized/CF (titanium plates were sandblasted and anodized; CFRPs were as received); Ti-Anodized/CF Si-CNT (titanium plates were sandblasted and anodized; CFRPs were treated using silane and carbon nanotubes (CNT)). The inter-laminar fracture toughness of the FMLs was evaluated by performing a (SCB) test. Here, the specimen is fixed at one end, and a force is imposed at the other end with a pre-crack of known dimensions. Specimens were tested at 2 mm/min on an Instron universal testing machine (Model 5569) for each FML system. Ti-Anodized/CF system showed a much higher (1222%) inter-laminar fracture toughness than the other samples. Moreover, the surface treatment of CF leads to a further 12.1% increase in interfacial fracture energy of the dry Ti-Anodized/CF-Si-CNT.

VII. Conclusions

The above research has shown that treating the titanium sheets significantly increases the mechanical properties of the Ti-CFRP interface. As such, further research can be done in investigating new methodologies of increasing the surface roughness and porosity of the titanium sheets. Furthermore, most studies focus merely on treating the titanium sheets; however, investigating the effect of treating CFRP plies as well could lead to further improvements in mechanical properties in these types of FMLs. Finally, coating of external surfaces with substances inert to environmental attacks could be considered as an alternative method to further improve the material performances.

References

[1] Cortes, P., Cantwell, W.J. (2006). Structure-Properties Relations in Titanium-Based Thermoplastic Fiber-Metal Laminates. Polymer Composites, 27(3), 264-270. DOI: 10.1002/pc.20189

[2] Hu, Y. B., Li, H. G., Cai, L., Zhu, J. P., Pan, L., Xu, J., Tao, J. (2014). Preparation and properties of Fibre-Metal Laminates based on carbon fibre reinforced PMR polyimide. Composites: Part B, 69, 587-591. DOI: https://doi.org/10.1016/j.compositesb.2014.11.011.

[3] Li, X., Zhang, X., Zhang, H., Yang, J., Nia, A. B., Chai, G. B. (2016). Mechanical behaviors of Ti/CFRP/Ti laminates with different surface treatments of titanium sheets. Composite Structures, 163, 21-31. DOI: https://doi.org/10.1016/j.compstruct.2016.12.033.

[4] Matikas, T.E., Karpur, P. (1993). Ultrasonic reflectivity technique for the characterization of fiber-matrix interface in metal matrix composites. Journal of Applied Physics, 74(1), 228-236. DOI: 10.1063/1.354150

[5] Molitor, P., Barron, V., Young, T. (2000). Surface treatment of titanium for adhesive bonding to polymer composites: a review. International Journal of Adhesion & Adhesives, 21, 129-139. DOI: https://doi.org/10.1016/S0143-7496(00)00044-0.

[6] Sinmazcelik, T., Avcu, E., Bora, M. O., Coban, O (2011). A review: Fibre metal laminates, background, bonding types and applied test methods. Materials and Design, 32(7), 3671-3685. DOI: https://doi.org/10.1016/j.matdes.2011.03.011.

[7] Truong, H., Lagoudas, D., Ochoa, O., Lafdi, K. (2014). Fracture toughness of fiber metal laminates: Carbon nanotube modified Ti- polymer-matrix composite interface. Journal of Composite Materials, 48(22). 2697-2710. DOI: 10.1177/0021998313501923.

[8] Wang, X., Ahn, J., Kaboglu, C., Yu, L., Blackman, B. R. K. (2016). Characterization of composite-titanium alloy hybrid joints using digital image correlation (DIC). Composite Structures, 140, 702-711. DOI: https://doi.org/10.1016/j.compstruct.2015.12.023

[9] Yu, B., He, P., Jiang, Z., Yang, J. (2017). Interlaminar fracture properties of surface treated Ti-CFPR hybrid composites under long-term hygrothermal conditions. Composites: Part A, 96, 9-17. DOI: https://doi.org/10.1016/j.compositesa.2017.02.011.

Commenti